U-Beaut Polishe's Swansdown Polishing Mop

These genuine Swansdown mops are made right here in Australia and are one of the best ways we have found to put a brilliant wax finish onto timber especially if you are using our EEE-Ultra Shine, Traditional Wax or both. They also work extremely well with Shellawax and Shellawax Cream.

Using one of these mops can cut the time it takes to buff a wax finish to a matter of seconds, depending upon the size of the work to be buffed. A tabletop will only take an couple of minutes easy work with the 100 fold buff compared to around 15 minutes or more of arm wrenching, back aching hand rubbing. It will leave a much nicer shine on the timber because it is working with the grain rather than putting swirls on the surface that you would get from using a lambs-wool buff, which works with a circular motion. These mops also work much cooler than a lambs-wool buff in a drill or angle grinder, making them much safer to use on surfaces that may be effected by heat.

The mops are made of genuine swansdown which is woven to form a soft fabric sheet of material called a fold these sheets are put together in a stack of 50, 75 , or 100, cut to size, securely fastened between two heavy washers and finally the centre hole is punched out.

We have 3 sizes of mop 100mm (4") diameter x 50 fold 150mm (6") x 75 fold, and 150mm x 100 fold.

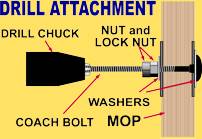

The photo to the above shows the 150mm (6") x 100 fold mop being used with a drill. It is ideal for buffing large areas as it spreads to around 115mm (4.5") across its buffing surface when in use, making it easy to cover a large area with each pass. A tabletop with a width of 1 metre can easily be buffed in no more than 10 passes of the mop.

SWANSDOWN BUFF ON THE LATHE

For buffing bowls and other hand held objects.

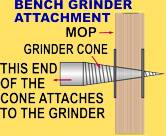

Above and below the mop is attached to the lathe via a long coach bolt which fits snugly through a timber cone and then into a screw chuck. This same fixing could be used with a faceplate, scroll chuck and other chucks.

|  |  |

On the lathe the 100mm x 50 fold mop can be used both inside and out on bowls and is ideal for buffing work that cant be finished in the lathe as well as small boxes, jewellery, carvings and more.

THREE IDEAS FOR USING THE SWANSDOWN MOPS

When these mops are new they will shed a lot of fluff the first few times they are used, to minimize and control this shedding it is a good idea to condition the mop before using it. This is done by running the mop at high speed then putting a piece of very course abrasive (16 grit is ideal) in contact with the edge of the mop that is used for buffing. This will drag off any of the loose fibres with a controlled action. This can also be done using a hacksaw blade and a bit of care.

Trusted By

We are a small operation specialising in servicing the needs of woodturners and woodworkers in Australia and around the globe. With a small team of friendly staff we are ready to help you with your woodworking needs. Orders can be placed over the phone, online or you can pop into the shop to make your purchase...Read more