Jigsaw blade selection can make a huge difference to the performance and cut quality of any jigsaw, but with so many available types - how do you choose the right one?

In order to make it a bit easier to find the right Festool jigsaw blades for your next project, we've put together this handy guide.

We'll go over five tips that cover:

- Jigsaw blade mount types

- Jigsaw blade lengths

- Jigsaw blade types & their suitable project materials

- Teeth configurations

- Jigsaw blade thickness

If you've ever asked yourself, "which jigsaw blade should I use?" or "is this the right blade type for my project?" then say no more, you're in the right place.

1. Blade mounts - T or U?

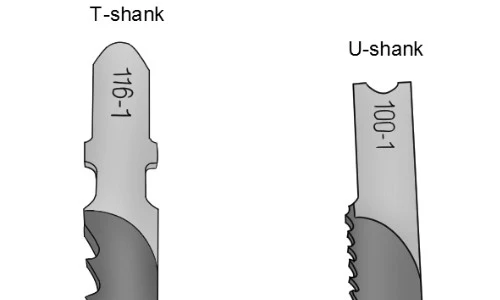

Your first step involves figuring out whether your jigsaw takes T shank or U shank blades (which you can identify by the shape of the end that goes into the machine).

You'll probably be all set with T-shank blades, as most modern jigsaws are now fitted with a tool-less blade change to make swapping blades quick and easy. U-shank blades are more common on older model jigsaws, and some saws accept both types.

2. Blade lengths

Size does matter - who would've thought?!

A blade that isn't long enough for the project you're working on can cause problems, so you'll want to make sure you've picked a suitable one if you're cutting through deep materials.

Two main things to keep in mind when reading blade lengths: Total Length (which runs from the tip of the shank to the tip of the blade) and Cutting Length (which relates to the actual part of the blade making the cut).

Overall, make sure you have enough cutting length to make it through your material and as a general rule of thumb, it's best to leave around 25mm of extra length to accommodate for the reciprocating movement of your jigsaw.

3. Types of blades & their suitable project materials

Depending on the material you're cutting, it's important to pick the right jigsaw blade. There are four main jigsaw blade types and using the right one helps ensure a cleaner cut and increases the longevity of your blades.

The four main blade types are:

-

High Carbon Steel (HCS)

Project materials: best suited for softer materials such as soft woods, light duty plastics and wood fibre boards like MDF.

Features: though it may dull quicker, this softer, less expensive steel has more flexibility, making it well suited for scroll cutting. -

High Speed Steel (HSS)

Project materials: best suited for cutting harder materials such as metal, copper, aluminium, perspex and other non-ferrous metals.

Features: these blades are generally harder and have higher abrasive resistance so they will cut faster and have greater longevity. They can be stiff and inflexible though, so they're not as suitable for bends and curves which can cause the blade to break prematurely. -

Bi-Metal (BIM)

Project materials: choose bimetal blades for cutting harder wood, metal and laminates, especially if cutting curves.

Features: these jigsaw blades combine the flexibility of HCS with the durability of HSS, creating a blade that can flex without breaking and cut curves through hard materials without dulling the teeth. -

Tungsten Carbide (TC)

Uses: Commonly used when cutting through abrasive materials like kitchen or bathroom tiles, fiber cement boards, plasterboard or glass fibre reinforced plastics

Features: TC blades have carbide teeth or, more commonly, a layer of tungsten carbide grit which is applied to the cutting edge instead of saw teeth.

4. Teeth configurations

The number of teeth per inch (TPI) is the main thing to keep in mind here, and it determines the speed at which the blade cuts efficiently. A higher TPI makes for a smoother but slower cut, whereas a lower TPI results in a rougher but faster cut.

The workpiece you're cutting can also play a large part: jigsaw blades for metal can quickly be identified by their especially fine teeth, while a coarse cutting blade for soft woods will typically have much larger teeth which enable it to quickly power through the material.

Aside from this, the shape and arrangement of your blade's teeth can also influence how it cuts. Without wanting to get too in depth in this quick guide, we've included an outline of the two main types below.

- Milled Teeth - this type of setting on the teeth helps cut faster and reduce the wear and tear on a blade allowing them to last longer.

- Ground Teeth - this type of setting produces a smoother cutline, but they cut slower and they can get very hot.

Overall, it's best to read your blade packaging or ask your shop assistant to get the best sense of your blade's particular strengths and best applications, and then go from there.

5. Blade thickness

Quick tip: to ensure straighter cuts (especially when cutting thicker materials), use a jigsaw blade with increased thickness.

Jigsaw blades can sometimes leave angled cuts through thicker materials if the end of the blade starts to wander during a cut. This is an inherent limitation of jigsaws themselves, as jigsaw blades are long, thin strips of metal which are only supported by the tool at the shank end.

No need to fret though - in many cases it can be overcome by careful blade choice.

Conclusion

So there it is! Five key tips that cover what you need to know when buying jigsaw blades.

One thing to keep in mind is that this is a high-level guide that covers only some of the many options available on the market. To ensure you're using your blades properly and making the most of them, it's best to read the manufacturer's descriptions and follow their recommended guidelines.

If you found this helpful and are interested in more tips and tricks to help you create more with wood, leave your email down below.

Leave a comment